Manufacturer of mechanical parts by cold thread rolling

Cold thread rolling means

- Rolling machines from 30 until 100 Tons

- NC Rolling machine

- 300 rolling tools sets are available to manufacture nearly every type of thread before or after heat treament

Capabilities

- ø 6 à 150 mm

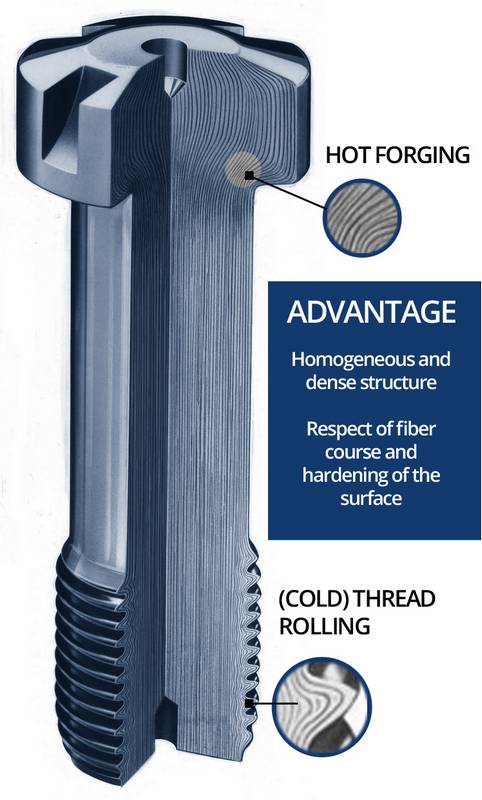

Advantages of thread rolling for mechanical parts

- Respect of fiber course and hardening of the surface.

- Better fatigue strength: cold thread rolling ensures a maximal compression during the whole deformation, improving therefore thread resistance and avoiding any defect that may occur with machined threads

- Surface rendering

- Reduced machining time

- Mastering of thread rolling process : no marks due to tool wear

Thread rolling process improves thread resistance.

Videos : thread rolling